Dedicated to energy management, the ISO 50001 standard focuses on improving the energy performance of organizations in all sectors. If you want to get started however, note that its application is relatively technical and cannot be done without preparation. To help you understand the challenges of achieving an ISO 50001 certification, we have reviewed the challenges involved when implementing an energy management system in the industrial sector, and the advantages of using a digital solution in this context.

The ISO 50001 standard in a few words

Published in 2011, this standard is intended for organizations that want to improve their energy performance. It provides them with a clear and structured framework for developing an energy management system. The 50001 standard therefore helps companies make more efficient use of energy, reduce their consumption and costs, and limit their impact on the environment.

The ISO 50001 Standard: Parameters and Implementation

A few reminders about the standard

Following on from the ISO 9001 and 14001 standards, the ISO 50001 standard is based on the same structure, but also has a much more important technical dimension than its counterparts in terms of quality and the environment.

To gain this certification, a manufacturer must prove its ability to manage energy efficiently, while also being able to demonstrate that it is capable of setting up specific processes and document tracking. This involves managing technical information, tracing it, and making it available to stakeholders in the form of an archive.

The standard also has a significant economic dimension, taking into account the expenses in relation to the profits, and therefore the payback. If the purpose is, above all, to reduce the company’s energy footprint, the goals can be adjusted according to the lever on which the company wishes to act.

Expert needs

The ISO 9001, 14001 and 50001 standards may have the same structure, but the technical content to be managed proves to be more significant regarding the theme of energy. As a result, it is essential to have some expertise on the subject of energy to obtain a good understanding of the subject. This explains why companies are sometimes obliged to call on external expertise for the implementation of the energy management system.

The major projects of the standard

A management system can in no way be one person’s responsibility. This is why it is necessary to set up an organization that involves several people, including senior management.

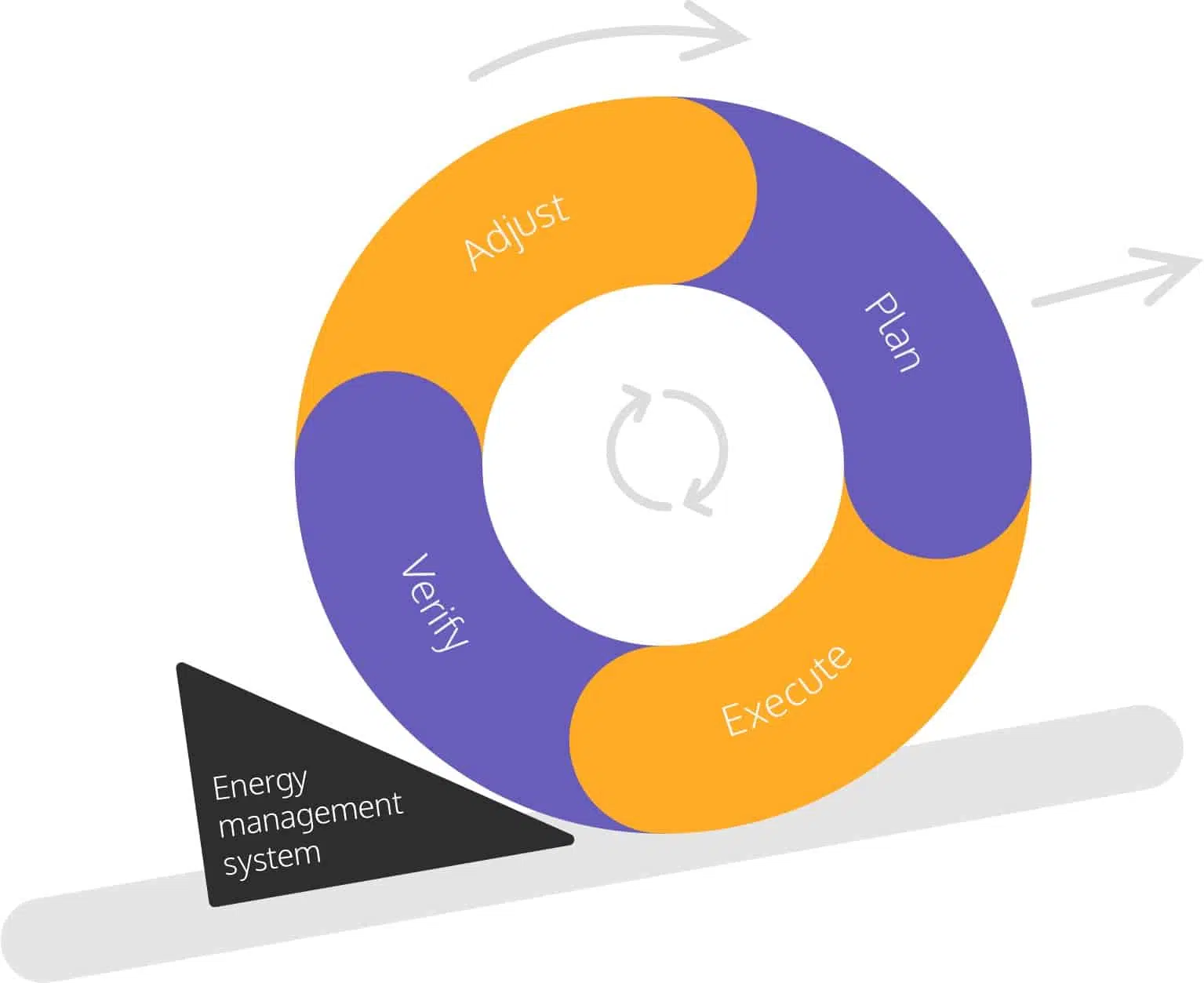

A managerial structure must therefore be created, and work according to a multi-stage methodology: observation, recommendations, defining objectives, implementing projects, periodic review, corrective actions. This is the virtuous circle of continuous improvement, outlined in the form of a wheel: the PDCA (Plan, Do, Check, Act).

Following this logic, the energy review and the audit consists of monitoring energy flows for all transformation activities, in order to analyze the energy performance as things stand. It is then a matter of detecting significant energy use (SEU) before implementing actions for improvement.

Significant Energy Use (SEU)

A use that is energy intensive or represents a significant amount of energy consumption, or represents a significant potential for performance improvement. At the site or company level, the energy consumption of all SEUs should be minimum 80% of total consumption. But be careful! Simply listing the most energy-intensive uses does not constitute taking an energy management approach. In addition, you must be able to control them by modelling the performance of the systems studied, taking into account the various constraints they must meet.

The 5 benefits of a digital solution for implementing the iso 50001 standard

1. Better management of energy performance indicators (EPIs)

Due to a lack of time, these notorious indicators are often limited. For example, in industry, to a measurement of kWh consumed in each production unit. By using a digital tool, one can go far beyond these KPIs that are just too generalised and not complex enough.

2. A view of the situation in real time

With the right EPIs and a view in real time, it is possible to act immediately when an anomaly is detected. In setting up an energy management system, it is not enough to simply extract data and analyse it on the basis of archives. You must also be able to implement corrective measures as soon as possible. This is totally impossible to do with manual data analysis.

3. Making energy mapping available

On a digital platform such as METRON's, energy mapping (electric meters, steam meters...) is offered in the form of a dashboard facilitating the choice of the SEU. Depending on the context and the conditions of use of the equipment (temperature, nature of the product, operating time of the production lines...), it enables you to have an accurate view of all the factors that impact energy consumption and, what's more, correlate them with each other.

4. Fast and reliable audit support

The main advantage of a digital solution is to provide a critical, objective and analytical view on energy data. This means that, during an audit, the auditor can be quickly and reliably informed of the information kept. This enriched data visualization brings important added value for the energy manager, who as a result will have at their disposal both qualitative and quantitative elements to help them in their decision making.

5. Decision support for exceeding the standard's requirements

For each SEU, EPIs are defined according to the objectives and deadlines set for achieving them. With the ISO 50001 standard, we find ourselves in an improvement project that requires us to quantify the results obtained. With a modular digital solution, it is possible to launch the approach on an energy management basis and then add optimisation modules that are specific to a particular asset, utility or process.

While it is possible to obtain ISO 50001 certification with manual readings and Excel spreadsheets, this way of operating can be a source of errors, constitute a significant waste of time and limit your ability to analyze the situation. With a digital solution, you can have an enlightened vision of the data to define the areas for improvement and the actions to be taken within a given time frame. It also allows you to go further in optimizing the system by establishing hypotheses and contextualized scenarios, or to bring teams together around the project by providing the right information at the right time to the right person. Do you want to start the ISO 50001 process? METRON can assist you in implementing your energy management system thanks to an energy intelligence platform.